Choose an OEM auto parts manufacturer in Noida that pairs strong engineering (DFM and in-house tooling) with scalable plastic injection molding capacity, integrated finishes (vacuum metalising, hot foil stamping, pad printing on plastic, PU coatings), and automation for repeatability. Local presence, clear QA processes, and client references ensure predictable lead times and production-ready parts. Rustagi Polymers is one of the leading auto parts manufacturers in Noida, offering end-to-end solutions from prototype to high-volume production.

Why Choosing the Right OEM in Noida Matters?

Noida and Greater Noida are established manufacturing hubs with strong supply chains and logistics. Sourcing locally from a reputable OEM auto parts manufacturer in Noida reduces lead time, simplifies quality control visits, and speeds issue resolution. For auto parts—where tolerances, material properties and finishes are critical—choosing a partner who understands both plastic injection molding needs and advanced surface finishes (like vacuum metalising and hot stamping foil processes) is essential.

1. Start with engineering & tooling capability

What to verify

- In-house mold design, maintenance and DFM (Design for Manufacturability) reviews.

- Prototyping capability and first-article inspection (FAI) workflows.

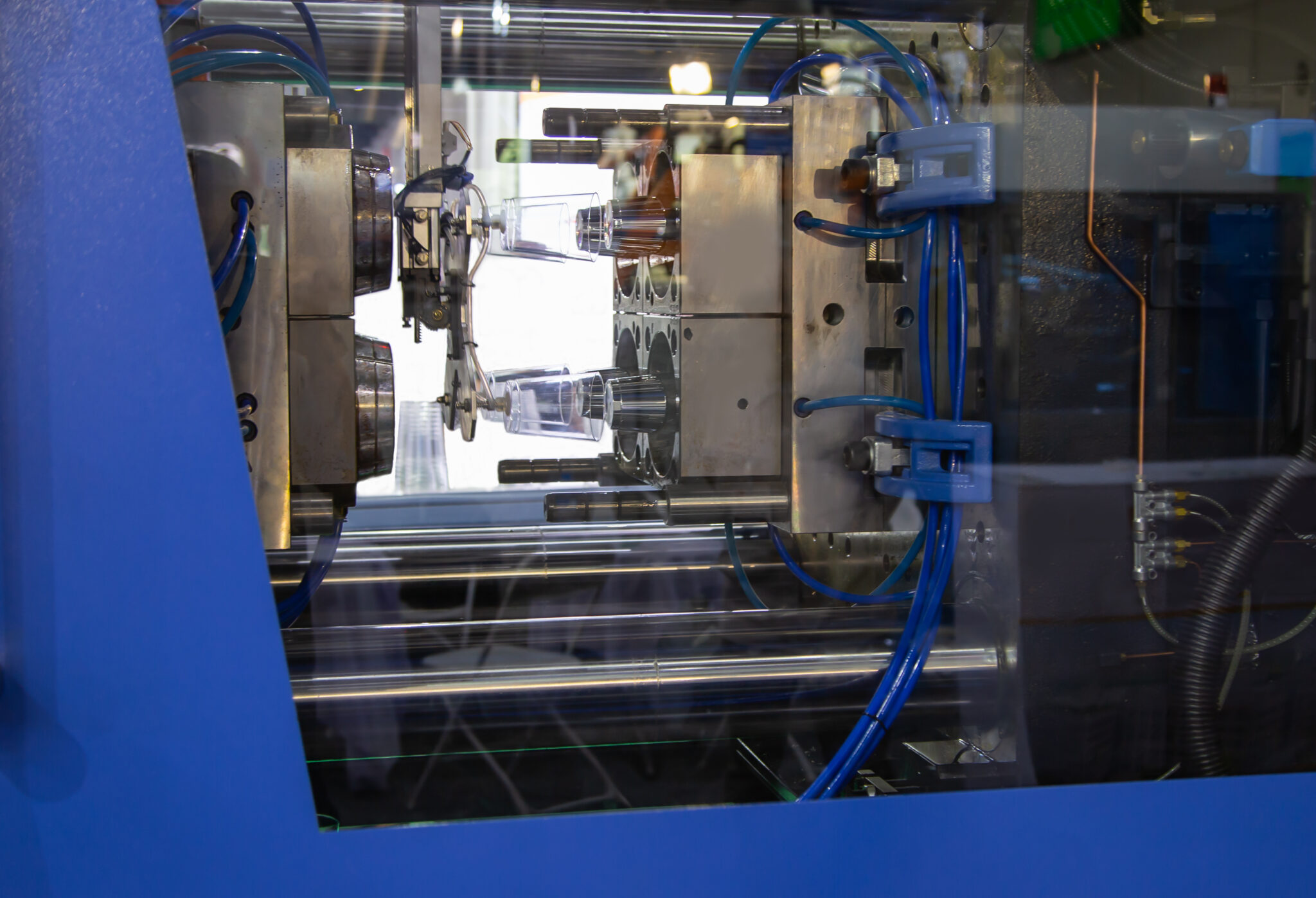

- Machine park diversity (multi-tonnage injection presses) to support small precision parts and larger housings.

- Experience with automotive-grade polymers (ABS, PP, PC, PBT, etc.) and insert injection molding where needed.

Why it matters

A manufacturer strong in tooling and DFM reduces rework, lowers upfront tooling costs, and shortens time-to-market. Ask for recent tooling lead times and examples of parts produced to verify competence.

2. Verify finishing & surface-treatment expertise

Automotive parts often need both functional and decorative finishing. Prefer OEMs that offer these services in-house to minimize handoffs and variation:

Key finishes to check

- Spray painting / plastic painting service and PU coating services on plastic for color stability and durability.

- Vacuum metalising / UV metallising for reflective and metallic components (e.g., reflectors, trims).

- Hot foil stamping and foil stamp printing for premium branding on trims and badges.

- Hydrographics water transfer printing for complex patterns and full-coverage designs on irregular shapes.

- Pad printing on plastic for logos, icons and functional markings.

Why in-house finishing helps

When finishing is integrated with molding, parts arrive production-ready—reducing logistics, handling damage, and additional QC steps. It also enables concurrency (finishing process development in parallel with tooling) for faster launches.

3. Quality systems, testing & compliance

Ask about

- Material traceability and batch records.

- Dimensional inspection methods (CMM, optical gauges), cosmetic inspection protocols, and SPC (statistical process control).

- Environmental and flammability testing if your parts require it.

- Certifications (ISO 9001, IATF 16949 if available) and ability to provide FAI reports.

What good QA delivers

Consistent tolerances, fewer rejects, and predictable scaling from pilot to production—critical for automotive supply chains.

4. Automation, process control & scalability

Look for

- Automated molding/handling and automated finishing lines (e.g., automated hydrographic dipping, automated spray lines).

- Real-time monitoring and process-control systems to reduce variance.

- Multi-facility capacity or scalable production plans to support spikes in demand.

Customer impact

Automation improves batch-to-batch consistency and shortens cycle times—translating into reliable lead times and reduced total cost of ownership.

5. Industry experience & references

Check

- Case studies or client lists showing automotive experience (interior trims, housings, caps, assemblies).

- References from OEMs or Tier-1 suppliers.

- Examples of parts that required complex finishes (foil stamping on plastic, vacuum metallising).

Why it matters

Proven experience reduces onboarding friction and demonstrates capability to meet automotive quality expectations.

6. Logistics, location & support

Practical considerations

- Proximity to your facilities or primary assembly plants (Noida-based suppliers reduce transit time).

- Flexibility for on-site visits, sample approvals, and emergency runs.

- Packaging and protective finishing procedures to prevent damage during transit.

Why a one-roof partner matters for OEMs

Choosing a plastic injection molding company that also offers finishing—hot foil stamping, vacuum metalising, pad printing on plastic, and PU coating services on plastic—reduces supplier complexity, shortens lead times and helps ensure consistent aesthetics and durability. Rustagi Polymers’ integrated approach (molding + finishes + automation) is designed to deliver production-ready automotive components with fewer touchpoints and predictable quality. This is one reason Rustagi Polymers is recognized among leading auto parts manufacturers in Noida.

Rustagi Polymers - Your One Stop Solution

Rustagi Polymers operates facilities in Noida and Greater Noida, combining plastic injection molding capacity with advanced finishing: spray painting, PU coating, hot foil stamping, vacuum/UV metallising, hydrographics water transfer printing, and pad printing on plastic. Our investments in automation and quality systems help OEMs scale from prototypes to high-volume production reliably.

Why Rustagi Polymers is Considered The Best Auto Parts Manufacturer in Noida ?

- Rustagi Polymers provides end-to-end solutions for plastic components, combining precision engineering, high-quality injection molding, and advanced finishing processes under one roof including hot foil stamping, vacuum metalizing, and hydrographics water transfer printing.

- Offers in-house tooling, and prototyping to ensure efficient and optimized production.

- Ensures quality, consistency, and scalability at every step of production, from low-volume prototypes to high-volume runs.

- Experienced team guarantees dimensional accuracy, surface finish excellence, and functional performance to meet OEM requirements.

- Equipped with state-of-the-art machinery and automated finishing lines, complemented by strict quality control systems.

- Parts manufactured meet OEM specifications while enhancing brand perception.

- Known for innovation, reliability, and client-focused solutions, making Rustagi Polymers a preferred choice for auto parts manufacturers in Noida and across India.

- Trusted for timely delivery, competitive pricing, and superior craftsmanship.

Take the next step toward high-quality, production-ready automotive components — request a sample part, a free DFM review, or a custom quote today and see how Rustagi Polymers can transform your designs into premium, durable, and market-ready products.

FAQs

Q1: Can a single OEM handle both prototypes and large-volume production?

A: Yes. The best plastic injection molding companies support low-volume prototypes with quick-tool solutions and scale to high-volume production using hardened tooling and automation after validation.

Q2: How do I verify an OEM’s quality processes?

A: Request process documentation: DFM reports, FAI samples, SPC charts, inspection checklists, and any relevant certifications (ISO/IATF). On-site audits are also useful.

Q3: What finishing options improve perceived value on automotive trims?

A: Metallic looks (vacuum metalising), premium logos (hot foil stamping using hot stamping foil), high-quality paint/PU coatings, and custom patterns (hydrographics) all elevate perceived value while meeting functional requirements.

Q4. How long does tooling take for an injection molded auto part?

Tooling lead time varies by complexity and steel grade but typically ranges from 4–12 weeks; complex, multi-cavity steel molds can take longer.

Q5. What is the typical cost to tool an injection mold?

Tooling costs depend on cavity count and steel vs aluminium tooling; expect anywhere from approximately ₹1.3 lakh – ₹4.5 lakh for quick/soft prototype tools to around ₹22 lakh – ₹90 lakh (or more) for hardened steel production tools.