Starting from the casing of common electronics to even the dashboard of your new car, plastic injection moulding is found all around. After all, it is one of the most scalable and trustworthy manufacturing processes used today.

Are you wondering how a simple plastic injection process produces quality molds? Let’s understand what is a plastic injection moulding?

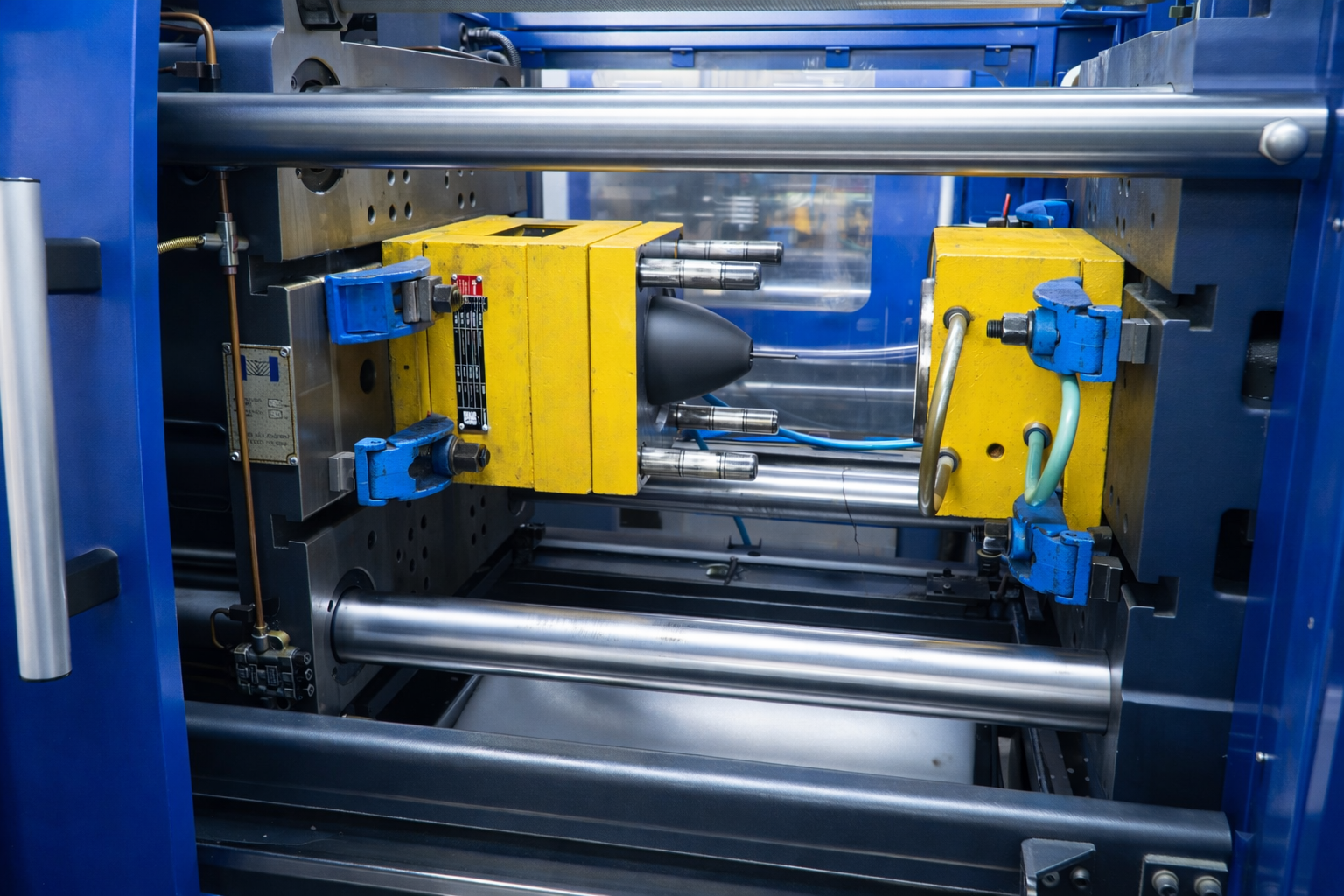

Plastic injection is a step-by-step process where molten plastic is injected into a metal mould, which cools down in order to produce products such as automotive components, bottle caps and cosmetic packaging.

Today, we will discuss the journey of how injection moulding works, types of moulds used in the process, materials used and what all equipment is required. Let’s also understand why manufacturers across India, especially auto parts manufacturers in Noida, trust this state-of-the-art technology.

What are the different types of moulds used in the process?

There are different products that demand different mould designs, particular to the industries. The common mould types include the following:

1. Single-Cavity Moulds

Single-cavity moulds are highly suitable for low-volume production of plastic parts, commonly used in plastic painting services. In this scenario, the mould has only one cavity which is capable of producing a single part at a time. Ideal choice for precision or low-volume components required mostly by small-scale factories.

2. Multi-Cavity Moulds

On the other hand, multi-cavity moulds have multiple cavities that allow manufacturers to produce more than a single mould in one cycle. This enables manufacturing units to produce multiple identical parts in one cycle which increases productivity and saves time.

3. Family Moulds

To make manufacturing more efficient and effective, manufacturers opt for family moulds. The family injection mould is an effective tool that enables the factories to produce multiple parts with various features.

4. Hot Runner Moulds

In automotive and plastic components, a hot runner is a molten plastic conveying unit that is used within the injection mould. This reduces cycle time and improves the mould quality and efficiency. In the long term, it delivers greater flexibility and better part aesthetics.

5. Cold Runner Moulds

In this case, the injection moulding system makes use of two or three plates during plastic injection moulding. Cold runners are popularly known as unheated channels which makes them a convenient option for transfering plastic from the moulding machine to the mould cavities.

What is the difference between thermoplastics and thermosets?

Moving forward, let’s take a closer look at the basic definition, applications and functionality of thermoplastics and thermosets.

Thermoplastics

Under the heat, thermoplastics soften and once cooled down, the material begins to harden again. Thermoplastics can be reheated and reshaped in multiple shapes and forms as per the specific requirements. Widely used for components requiring final finishing, like pad printing on plastic or hydro water transfer printing.

Thermosets

Thermosets are a type of plastic formed by permanently hardening a soft solid. It also supports liquid prepolymer (resin), which is usually known as curing. Easy to work with and highly preferred for delivering effective results for high-temperature applications.

What is the process of plastic injection moulding?

To set up a complete injection moulding process, the below-given steps are followed:

1. Plastic Material Preparation

First, small plastic pellets (usually thermoplastics like ABS, polypropylene, or polyethene) are systematically fed into a hopper. These pellets contain additives which further help improve the overall efficiency, strength, colour, flexibility and build UV resistance.

2. Melting

Next, pellets drop from the hopper into a heated barrel. Inside the barrel, a rotating screw moves the pellets forward which further allows heat from the barrel to melt the pellets into a molten plastic using friction from the screw.

3. Injection

Once enough molten plastic is accumulated, the screw starts moving forward like a piston. Thereafter, the molten plastic is injected into a closed mould cavity (which takes place under high pressure). Finally, the mould usually made of steel or aluminium is shaped into its solid, final form.

4. Cooling

The plastic fills the mould and it starts to cool almost immediately. This happens because the cooling channels inside the mould circulate water or oil to speed up the solidification process. Towards the last stage of cooling, plastic begins to harden and transforms into the exact shape of the mould.

5. Ejection

Once cooled, the mould opens and ejector pins push the finished part out of the mould. The mould then closes again for the next cycle of moulding.

6. Repeat Cycle

The process repeats automatically. Wherein, cycle times can range from a few seconds to a few minutes, depending on part size and material. Many advanced units also integrate the best vacuum metallising in Greater Noida for chrome-like finishes on plastic components.

What is the impact of wall thickness on injection-moulded components?

The wall thickness of a mould ensures the quality and strength while improving the durability and appearance of components produced through plastic injection moulding. A well-designed part maintains the wall thickness, which promises smooth material flow and controlled temperature, mostly ensuring cooling.

When walls are too thick, the plastic takes longer to cool, which leads to sink marks, internal dysfunction, or complex cycles. On the other hand, walls that are too thin may cause incomplete filling, weak structural integrity, or flow hesitation during moulding.

What are the common injection moulding defects and quality issues?

Despite precision engineering, defects can occur if parameters are not fully tested and optimised:

- Sink Marks: These appear when thicker sections of the part cool more slowly than thinner areas, causing the surface to sink inward.

- Warping: When wall thickness isn’t uniform, different areas shrink at different rates, leading to uneven shrinkage.

- Short Shots: This happens when molten plastic doesn’t fully reach all areas of the mould due to low injection pressure and poor flow.

- Flash: Excess plastic seeps out of the mould’s parting line due to high pressure or worn tooling.

- Burn Marks: Trapped air inside the mould gets compressed and overheats, resulting in dark or charred marks.

What makes injection moulding the right manufacturing choice?

There are multiple reasons why plastic injection moulding is the ideal manufacturing solution, such as the following:

- Components that require premium surface finishes, such as hydro water transfer printing and pad printing on plastic.

- Cost-effective manufacturing over long production runs

- Automotive and industrial parts with consistent quality part requirements

- High-volume production of complex designs that require tight tolerances

For automotive and industrial components, especially those requiring secondary finishes, plastic injection moulding is the basis for quality component manufacturing. Rustagi Polymers offers a complete manufacturing ecosystem from vacuum metalizing to fully finished components that can be easily assembled for quick usage.

FAQs (Frequently Asked Questions)

1. How do processing windows affect long-term consistency in injection moulding?

Processing windows define the safe temperature, pressure, and cycle limits. Staying within this range ensures parts are produced consistently over time. Operating outside the window can lead to frequent defects and rejection.

2. Which process variables commonly cause dimensional defects in injection-moulded parts?

Common causes include inconsistent melt temperature, incorrect injection, uneven cooling, and improper cycle time. These variations can lead to warpage, shrinkage, or size inconsistency.

3. Which supporting systems are critical for injection moulding production?

Key systems include material drying units, temperature controllers, cooling systems, power backup, and quality monitoring tools. These systems keep the process in-check and prevent production interruptions.

4. How do automation systems improve injection moulding reliability at scale?

Automation reduces human error, ensures repeatable cycles, and maintains consistency. This leads to better output and quality control.

5. How do part orientation and gate location influence dimensional stability and cosmetic quality?

Proper orientation and gate placement allow uniform material flow and cooling. This reduces stress, prevents warping, and improves surface finish, ensuring accurate results.