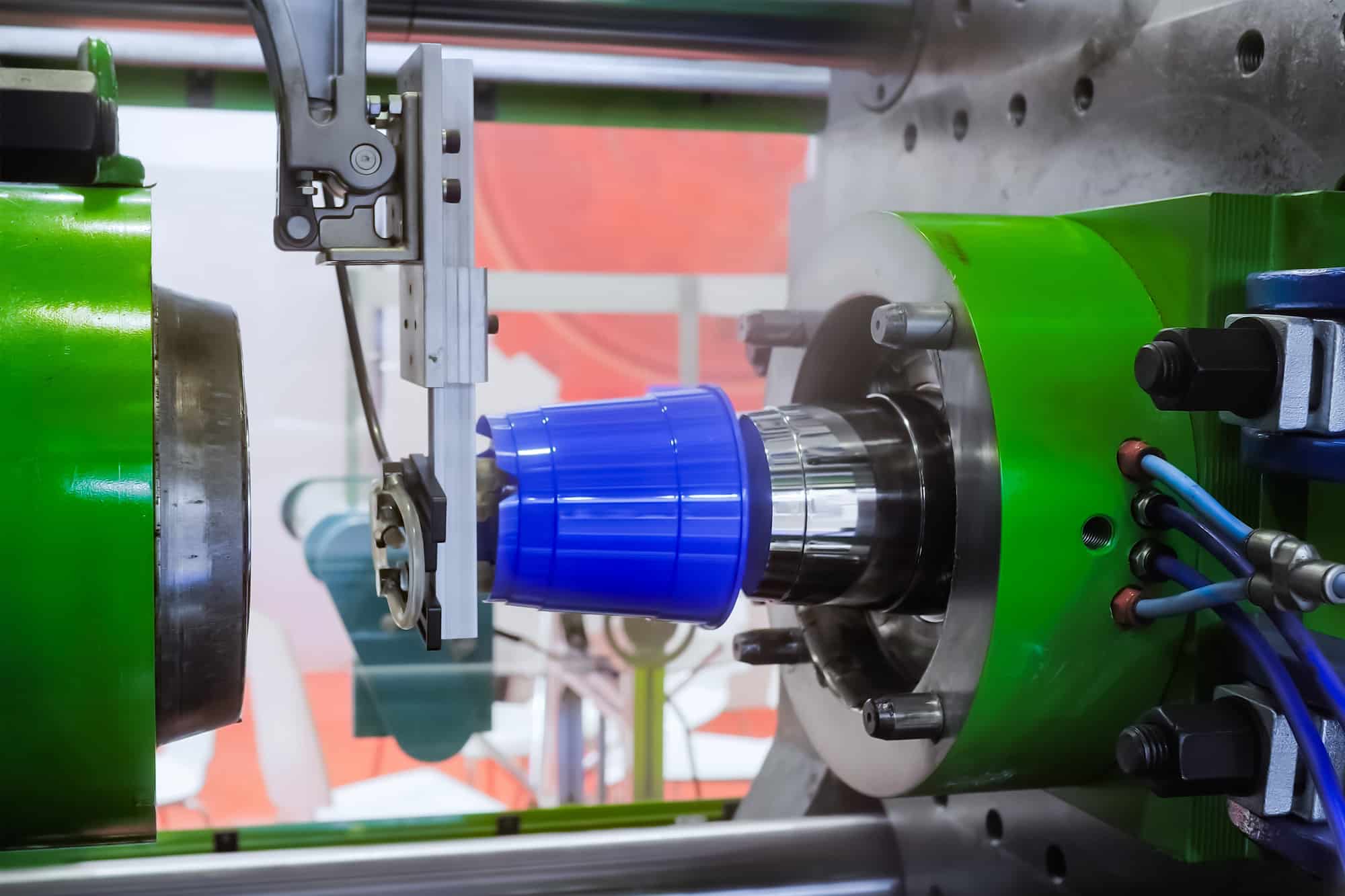

When planning plastic part production, prototyping is a critical first step. A reliable plastic moulding factory will often suggest prototyping before mass production begins — and for good reason. Let’s explore why this matters.

1. Reduce Risk and Catch Design Errors Early

Prototyping allows you to test your part design in a real-world context before investing in full tooling. Even small design flaws can lead to delays, poor performance, or costly mold changes later. By working with a plastic injection moulding service that offers prototyping, you can catch and fix these issues early.

2. Confirm Fit, Form, and Function

Physical prototypes help ensure your part not only looks right but also fits and functions properly. Dimensions, tolerances, and assembly requirements can all be tested using prototypes before committing to expensive production molds.

3. Validate Material Choice

Not all plastics behave the same. Prototyping gives you a chance to evaluate different materials for durability, heat resistance, flexibility, or surface finish. This is especially useful if your part will undergo post-processing, such as hydro water transfer printing or pu painting services, where the base material must work well with the finishing process.

4. Shorten Time to Market

While it may seem like prototyping adds an extra step, it often saves time overall. By working closely with your plastic moulding factory during the prototype stage, you reduce the risk of rework and delays later. This helps keep your project on schedule.

5. Ensure Better Quality in Mass Production

Prototyping lets both you and your plastic injection moulding service fine-tune mold design, part geometry, and production parameters. This leads to a smoother transition from prototype to mass production, ensuring consistent quality and minimizing waste.

At Rustagi Polymers, we help clients take their designs from concept to mass production efficiently. We offer prototyping as part of our complete plastic injection moulding service, ensuring every detail is right before scaling up production. We also provide hydro water transfer printing, pu painting services, and other value-added processes to give your parts the finish and performance they need.

Prototyping isn’t an optional extra — it’s a smart way to protect your investment, improve quality, and get products to market faster.